Hose Collar

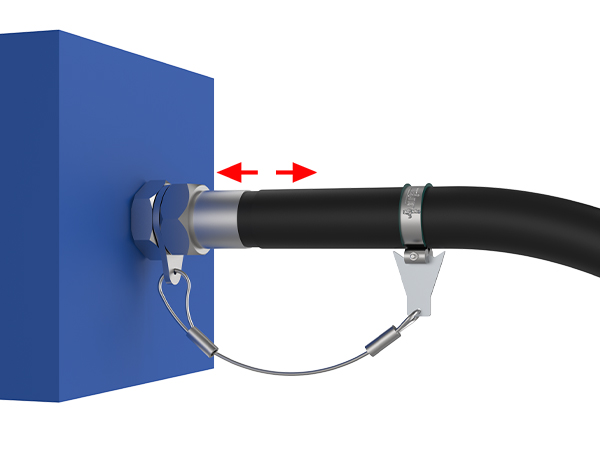

Hose collars are installed on the hose to secure the hose.

Hose whip restraining system is one of the most common accessories for fluid hoses in use and consists of two parts: the hose collar and hose whip restraint cable assemblies. The hose collar and one end of the cable assemblies are connected to the fluid hose and then fasten them to the port connector or flange connector.

When the hose is under high pressure, it is easy for a pressurised hose or hose fitting failure, while the hose whip restraint cable can limit the hose to a controlled range, preventing the hose or the splashing liquid from damaging the nearby equipment and injuring the operator near the faulty hose.

The "Hydraulic Safety cable" system does not operate during the step of disengaging the flexible hose, but, if applied correctly, it ensures that the hose is fully disengaged from the ferrule that restrains it. During this step, the flexible hose gains velocity and power due to the pressure increase of the oil contained therein.

During this step, the pressurised oil exits from the flexible hose. The hose begins to release the energy contained therein, and gains considerable velocity, triggering a hazardous "whip effect" which is very dangerous to anyone or anything in its vicinity.

Once the hose has been disengaged and the pressure released, the flexible hose can be restrained. This is where the "Hydraulic Safety cable" system gets into operation: the stainless steel cable is tensioned and deformed while the plate cuts into the rubber of the hose, preventing the clamp, firmly attached to the hose, from disengaging. The hose clamp and plate start to deform in turn, elastically absorbing the force released from the travel of the flexible hose.