Mar 14, 2022

DME Fitting Thread & Pipe Thread Introduction & Comparison

Niu Niu introduced the advantages and disadvantages of DME hose nipple and fitting seal. The sealing form of hose fitting is mainly realized by thread. Today, follow Niu Niu to learn about threads!

Hose assembly is the link of fluid transmission in hydraulic system, and its good sealing performance needs threads to ensure that sealing is the key to ensure the reliable operation of the system. The DME fitting thread we recommend to you can solve the sealing problem.

At present, there are three popular thread forms in the world: Metric standard, British standard and American standard. GB/T9065 and ISO 12151 adopt metric threads, and SAE J516-2019 and GB/T9065 adopt American threads.

History of Thread Development

Threaded parts are one of the earliest simple machines invented by human beings. In ancient times, threads were used to fasten armor to robes, press oil and make wine. After the first industrial revolution, the British invented screw spindle lathe, die and tap, which laid a technical foundation for mass production of threaded parts.

After that, how did the thread develop? (see below)

Types of Thread

Thread is mainly divided into connection thread, drive thread according to the purpose.

Pipe Thread

Among them, pipe thread in connection thread is the main way of pipe connection.

Pipe threads are divided into two systems: European standard, American standard. Domestic standard is basically on the American standard and European standard modification, modification mostly for the Metric system conversion, terminology expression, manufacturing and dimensional tolerance is basically the same. Both NPT and NPSC thread profile angles are 60°, while BSPP and BSPT thread profile angles are 55°. Thread form is divided into sealed (taper pipe thread) and unsealed (cylindrical pipe thread).

There are both domestic standards of 60° and 55°, which refer to ASME and ISO standards respectively.

-

British Standard Classification

BSP thread: The full name is British standard pipe thread, which belongs to Whitworh thread (BS 84), so the thread angle is 55°.

BSP is divided into BSPP and BSPT.

Name of BSPP

For historical reasons, BSPP has other different names. Common ones are BSPF (British Standard Pipe Fitting), BSPM (British Standard Pipe Mechanical) and PS (British Standard Pipe Straight). However, with the start of ISO standardization later, all these appellations were replaced by the letter G, which is the G thread.

G thread is divided into female and male thread, which is used for unsealed connection.

-

American Standard Classification

NPT. NPT is the abbreviation of National(American)Pipe Thread, which belongs to American standard 60°taper pipe thread (pipe thread with 60° thread angle and 1: 16 thread taper). NPT belongs to economical thread, which is commonly used in product design. NPT may have interference or clearance, so it needs sealing filler (sealing tape or sealant).

NPTF. This is a dry sealing taper pipe thread, only available in ASME American standard system. It completely depends on the thread itself to form a seal, and there is no sealing medium between the threads. The dry seal pipe thread provides a relatively strict tolerance, is a precision thread, only used in special occasions, in brittle hard materials with thin cross section using this thread can reduce the fracture phenomenon. NPTF male thread can be matched with NPTF, NPSF or NPSM female thread. NPTF pipe fitting is similar to BSPT pipe fitting but not interchangeable. Most sizes of threads have different pitch and profile Angle of 60°, while BSPT thread profile angle is 55°.

In addition, the characteristic code of dry seal cylindrical female thread for standard fuel in America is NPSF.

The characteristic code of American standard dry seal cylinder female thread is NPSI.

The characteristic code of SAE short dry seal taper pipe thread is PTF-SAE SHORT.

-

Metric standard classification

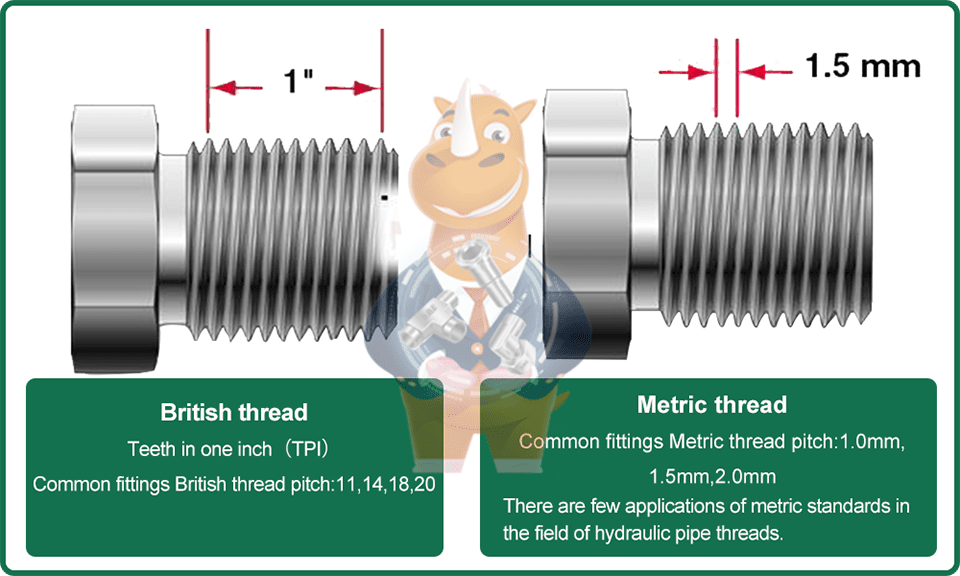

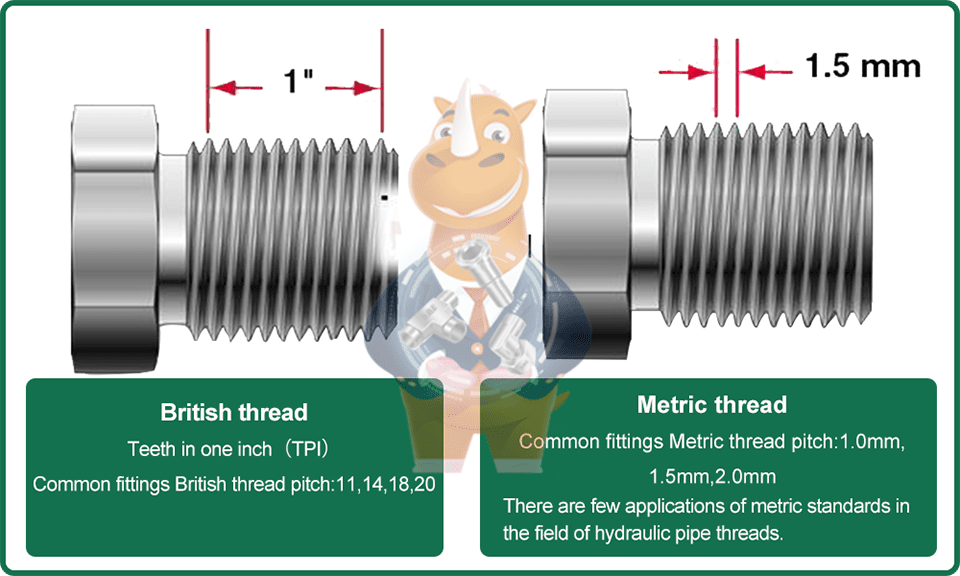

Metric thread is expressed by pitch, for example M20×1.5, 20 is the outer diameter, and 1.5 is the pitch. American and British threads are expressed by the number of threads per inch, which is the biggest difference. Metric threads are 60° equilateral, British threads are 55° isosceles. American thread 60° and Metric thread are in Metric units, while American and British thread are in British units.

37° cone (JIC) thread. The Society of Automotive Engineers (SAE) stipulates that 37° cone or seat can be used in high-pressure hydraulic pipeline. This kind of hose fitting is usually called JIC hose fitting. JIC male thread is straight thread which can only be matched with JIC female thread. JIC male thread is straight thread with 37° cone seat surface, and JIC female thread is also straight thread with 37°taper seat surface. The seal is formed at the 37° cone seat surface, and the threads of some sizes are the same as SAE45° cone angle threads, so the taper angle should be carefully measured to distinguish them.

Through the introduction of Niu Niu, we should have a deeper understanding of the fitting thread, choosing the correct fitting thread for hydraulic system is very important. The correct fitting with high-quality hose can get twice the result with half the effort in reproduction. DME&JDE Group production of fitting and hose far beyond the industry standard, is your best choice!

For more product information, please log in to official website:

https://www.dmejde.com (global services)

https://www.jidier.com (domestic services)

Or call us: 0086-19133858816

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文