Aug 25, 2023

ISO 50001 Energy Management System—© Powered by DME&JDE Group

DME as a key supplier of mechanical components, plays an important role in energy management. Through effective energy management, DME improves energy efficiency, reduces environmental impact, and achieves sustainable development. By applying ISO 50001, DME optimizes energy management to achieve innovation and sustainable development.

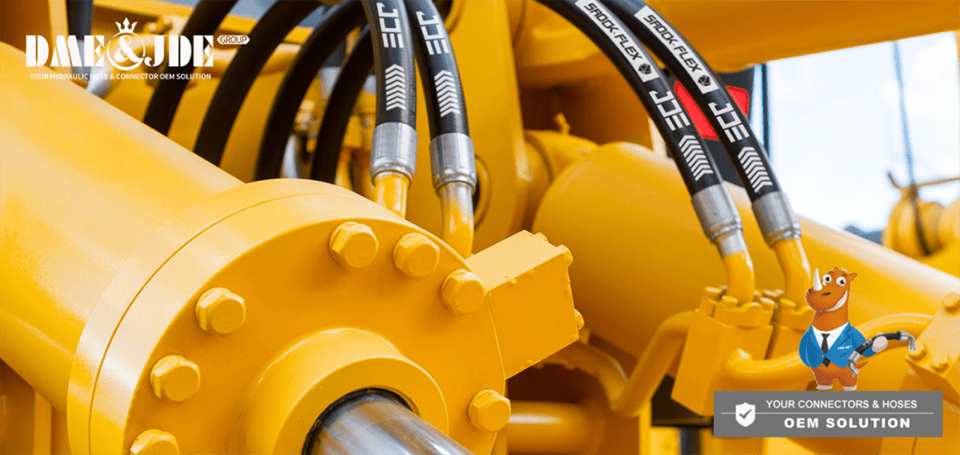

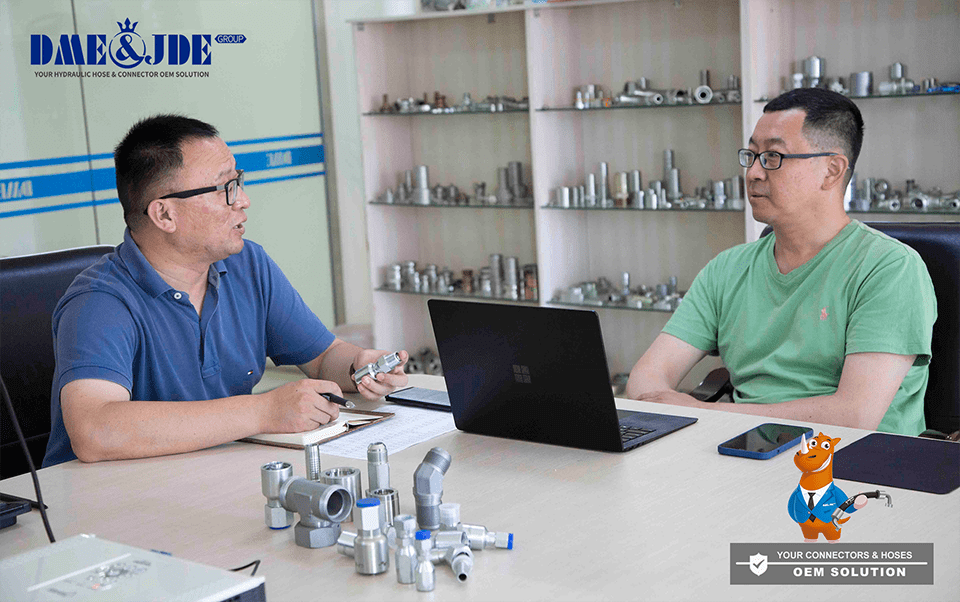

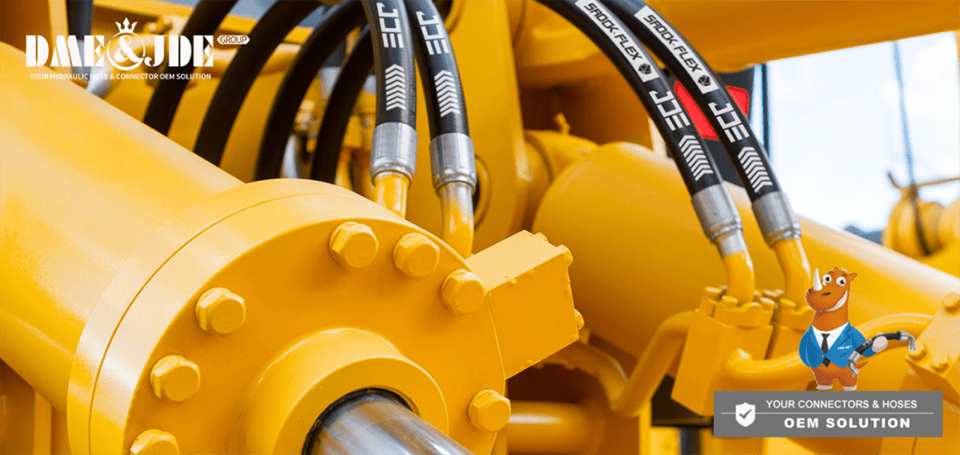

Hydraulic fittings are critical components for connecting and transmitting liquids or gases, widely used in engineering machinery, automobiles, aerospace, and other fields. As a key component of hydraulic systems, their efficiency and performance directly impact the overall system's operational effects.

Core Requirements of ISO 50001 Standard

ISO 50001 is an energy management system standard published by the International Organization for Standardization (ISO), aiming to help organizations establish effective energy management systems and continuous improvement. Through ISO 50001 certification, DME can ensure the standardization, sustainability, and continuous improvement of energy management.

- Establish Energy Policy

- Conduct Energy Planning

- Implement Energy Efficiency Improvement Measures

- Monitor and Measure Energy Performance

- Manage Energy Data

- Audit and Evaluate Energy Management Systems

- Organization and Employee Involvement

- Compliance and Legal Requirements

The core requirements of ISO 50001 standard focus on energy management, aiming to improve energy efficiency, reduce energy consumption, and promote sustainable development. By implementing these requirements, organizations can establish and maintain a systematic energy management system, continuously improve energy performance, and contribute to the long-term development of the organization.

1 Background and Significance of ISO 50001 Certification

- Importance of Energy Management in Enterprises

ISO 50001 certification helps DME implement an effective energy management system, optimize energy utilization, reduce energy consumption, greenhouse gas emissions, costs, enhance enterprise competitiveness and reputation, and promote sustainable development. Through this standard, DME can establish and maintain internationally recognized energy management systems, achieving coordinated progress in economy, environment, and society.

- Efforts and Adjustments Made To Apply for ISO 50001 Certification

By applying for this certification, all DME employees participated in learning and training, carried out comprehensive workshop improvements, enhanced equipment capabilities, and added fully automated material cutting machines.

Advantages of fully automated material cutting machines include:

- Improved production efficiency and effectiveness.

- Reduced labor costs.

- Improved cutting accuracy and consistency.

- Increased work safety.

- Programmability and flexibility.

2 Steps and Implementation Methods To Establish an Energy Management System

- Formulate Energy Policy

DME has established a clear energy policy that aligns with the organization's strategic goals and operational requirements. The energy policy expresses DME's commitment to energy management and continuous improvement.

- Set Energy Objectives and Plans

DME formulates an energy management plan to ensure that energy objectives and energy plans align with the organization's operations and management activities. This plan considers energy consumption, energy performance indicators, and relevant regulatory requirements.

- Establish Energy Indicators and Monitoring System and Develop Energy Improvement Measures

DME formulates and implements energy-saving measures to improve energy utilization efficiency, reduce energy waste, and lower energy consumption. This includes technological improvements, process optimization, equipment upgrades, and energy management training.

- Establish Employee Training and Participation Mechanism

DME conducts regular internal and external audits of the energy management system to ensure its effectiveness and compliance. Audit results are used in the continuous improvement process and provide opportunities for feedback and corrective actions.

DME encourages employee participation and positive feedback, increasing employees' awareness and understanding of energy management and motivating them to engage in energy-saving activities and provide improvement suggestions.

3 Towards ISO 50001 Certification

- Importance of Sustainable Development and DME’s Social Responsibility

DME always focuses on sustainable development and social responsibility, not only in energy management and environmental protection but also in employee safety and welfare, creating more value for society for long-term development.

- Expected benefits

Through comprehensive implementation of ISO 50001 certification and adoption of innovative technologies, DME achieves reduced energy consumption, improved production efficiency, and reduced environmental impact. This not only benefits DME in cost reduction and competitiveness but also contributes to the development of a low-carbon economy and sustainable industries.

As one of the industries with high energy consumption and significant environmental impact, DME takes on social responsibility and takes proactive actions. In addition to optimizing energy management, it also focuses on waste management and reduction, rational use of water resources, and environmental protection. Measures include strengthening green supply chain management, selecting environmentally friendly materials, and promoting the application of circular economy models.

DME considers energy management as a strategic priority, involving all employees from internal to external, to promote energy conservation and environmental sustainability. Only through continuous improvement and innovation can DME better address industry development challenges and move towards a green and sustainable future. Let us walk the path of sustainable development together and create a better

![Several different types of DME&JDE flexible hoses are displayed.]()

![Several different types of DME&JDE fluid connector are displayed.]()

English

English 简体中文

简体中文